Marine Filtration Solutions

Over the past several decades, the maritime industry has been driving its attention towards environmental protection. They have been hiving attention greatly on addressing the issues that affect and threaten the oceans, including pollution of air and water, disaster management, and ship recycling.

What is Ballast water?

Ballast water can be freshwater or saltwater. It sits in the ballast tank ships, and cargo holds, which keeps the ship balanced. Its job is to provide stability and maneuverability during a voyage when ships are not carrying heavy enough cargo or need more stability due to rough seas.

The ballast water consists of bacteria, microbes, small invertebrates, eggs, cysts, and larvae of various species. Although ballast water provides safety for ships while sailing, it impacts ecology from carrying many marine species. Therefore, every ship includes important guidelines on Ballast water management.

View of ballast water exchange process onboard of a ship using flow-through method underway in open ocean.

Why is ballast water treated?

When ships release ballast water at a new port, they risk introducing alien species, from small fish to microorganisms, into the water around the new area. The introduction of invasive species can cause lower habitat quality and other dangers which can harm fish and protected species in the region.

Therefore, they treat ballast water before discharging to eliminate the introduction of invasive marine species. Although seawater filtration is crucial, there are challenges. For example, using specific engineering techniques that bear the high chloride levels in seawater can threaten the filter and its parts.

FLTR offers you a wide array of marine filtration solutions regardless of onshore, offshore, or onboard. We always ensure we understand your unique challenges and deliver the best filtration solutions to improve process performance and minimise the environmental impact.

BMG – Multi Basket Bernoulli Filter

BMG – Multi BasketBernoulli filters are fully automated self-cleaning options that can continuously perform water filtration in a pressurised environment. The filtration process readily removes debris coming into the system from process liquids and various natural water sources such as a lake or river.

Advantages of using Bernoulli filters

- Requires only a low washing pressure

- Easy to install

- Maintenance is easy

- Have only a few moving parts

- Pressure is stable in both clean and dirty conditions.

CBS-Centrifugal Oil Water Separators(cows) Eliminator-D Series

The new technology utilises a multistage centrifugal system. The system ensures 100% protection against water, moisture and particulate in fuel. These are common in marine propulsion stationary engines- generators, welding and pumping installations, etc.

Benefits of the CBS-Centrifugal Oil Water Separators(cows) Eliminator-D Series

- It has low flow restriction

- long life of filter elements.

- Easy to install

- Simple maintenance.

- Very high efficiency of water separation from fuel with complete protection of injection pump, nozzles from water, dust, etc.

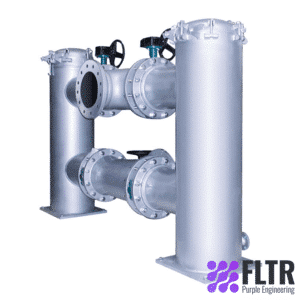

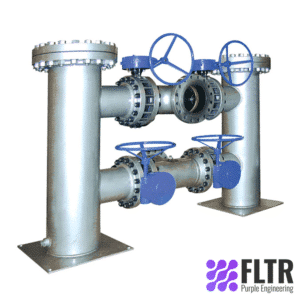

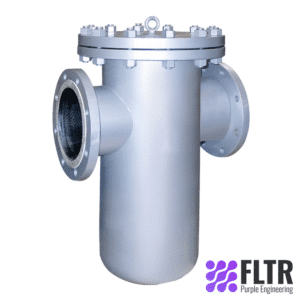

KW Series ANSI 300 Class Basket Strainer Housings

The Class Basket Strainer housings use stainless steel or carbon steel to withstand higher chloride levels in marine water, which endlessly threaten the filter with corrosion issues. ANSI 300 class simplex strainer housings effectively remove the effects of process liquids such as dirt, pipe scale, and other contaminants.

Process liquids can include water, chemicals, and petroleum products in many industrial filtration applications. Available sizes – 2 to 12 inches with 316 stainless steel or carbon steel standard material.

ANSI 300 class simplex strainer housings come equipped with a heavy-duty, perforated 304 stainless steel basket. Custom perforation sizes or mesh-lined baskets are also available. In addition, models include gauge taps with plugs on both the inlet and outlet sides.

Gauge taps allow for easy installation of pressure gauges to monitor differential pressure, which helps determine when basket cleaning is necessary. In addition, the strainers straight flow path and slanted design for applications with more frequent changes minimise pressure loss.

Typical markets include wastewater, pulp and paper, petrochemical, petroleum, oil and gas, transportation, marine, and food. These KW series ANSI 300 strainers are ideal for industrial and petrochemical filter applications with higher pressure and temperature requirements.

Features

- Cast carbon steel or 316 stainless steel bodies

- ANSI 300 class rated RF flanges

- Gauge taps with plugs are standard on all models

- 304 non-asbestos flat gasket seal standard, (other materials available) Bolted flange closure is standard, (optional cover designs are available)

- Includes adjustable, removable support legs on sizes 4″ and larger

- Tapped NPT blow-off with plug

- 304 stainless steel perforated basket included as standard (optional materials of construction available)

- Large basket area with the ability to collect substantial amounts of debris

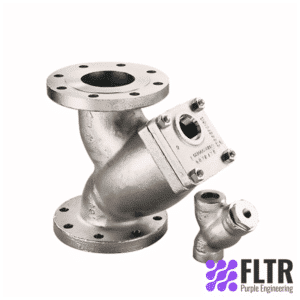

Model 90 1-48 inch

Model 90 Fabricated Simplex Strainer is fabricated with stainless steel or carbon steel to withstand higher chloride levels in marine water, which endlessly threaten the filter with corrosion issues. Customise to improve performance and meet higher pressure requirements.

The slant top design improves the flow through the strainer and results in significantly lower pressure drops. This design also results in a more compact basket. As a result, it weighs less than an ordinary basket, making it possible for one person to remove it when it comes time to clean or change out the basket.

ANSI Class 600, 900, 1500 or DIN EN flanges.

Options

- European standards – DIN/PED available

- Hinged cover or davit assembly for easier maintenance

- Alloy construction for body and baskets

- RTJ-style connections

- Vent valves

- Drain valves

- Gauge taps

- Backflushing system for manual or automated cleaning

- Pressure differential gauge and switches

- Steam jacket for highly viscous fluids

- Rotated or offset nozzle placement

- High-pressure capabilities

- Construction according to “AD 2000-Merkblätter”,DIN EN 13445 or ASME Code

- Brazilian NR-13 available

- Coatings and linings available upon request

Common modifications Model 90 1-48 inch

- Rotated inlet and outlet nozzles to eliminate an elbow in the downstream piping.

- Lowering or raising either the inlet or the outlet nozzle eliminates serious alignment and support problems.

Cover type openings

For applications with infrequent basket changing, FLTR offers a simple, cost-effective, bolted cover type. In addition, it’s available with a davit assembly cover for larger strainers with heavy covers. The design makes it possible for a one-person operation.

FLTR offers a hinged, quick opening cover secured by swing bolts for applications with more frequent changes. The cover is adaptable for higher pressure applications. For medium-sized strainers, 8″ to 16,” a davit assembly bolted cover is available, enabling one person to engage the hinge and open the lid.

Backflush/backwash option

In systems with heavy, well-defined solids and sediment, this option back flushes the system without shutting the system down. A piping connection with an on/off backflush valve at the strainer bottom connects to the strainer basket.

When solids accumulate in the bottom of the basket, the backflush valve opens, and the differential between the operating pressure and the back-flush system removes the solids. The second step, back-washing, reverses the flow and removes residual dirt.

Optional steam jacketing

Available in carbon steel or stainless steel rated for service up to 232 °C. These materials are ideal for the high temperatures required to process and transport heavy, viscous fluids without affecting the function or standard maintenance of the filter. Furthermore, steam jacketing maintains fluid temperature throughout the strainer.

Features

- Straight through flow design

- Low-pressure loss

- Slant top basket design

- Basket perforations from 1/32″ to 1″

- 20 to 400 mesh linings for fine straining applications

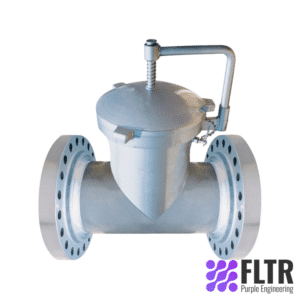

Model 91 T Type 2-48 inch

Model 91 T-Type Strainer is fabricated with stainless steel or carbon steel to withstand higher chloride levels in marine water. Unfortunately, chloride can cause corrosion issues to the filter.

Features

- ANSI class 150, 300, 600 or DIN EN flanges

- Vertical or horizontal orientation

- Low-pressure drop

- Convoluted screen for more surface area with perforations

- from 1/16″ to 1/2″

- 20 to 60 mesh linings for fine straining applications

Options

- Quick open hinged or davit cover assembly bolted cover

- Alloy construction for body and baskets

- Construction according to “AD 2000-Merkblätter”, DIN EN 13445

or ASME Code

- Steam jacket for highly viscous fluids

- Straight through or right-angle configuration

- Flanged class 600 or butt weld piping connections

Customise to improve performance and meet higher pressure requirements

The Model 91 fabricated T strainer, typically used for pump protection or other low solids applications, has several advantages compared to other strainer designs. Its compact design is perfect for applications with restricted space, and either vertical or horizontal installations are possible.

Furthermore, when cleaning the filter, draining the vessel is not necessary. It also can be adapted for straight-through or right-angle flow, making it ideal for retrofit situations.

Strainer design

The intricate design of the strainer screen doubles the screen area. Therefore, it completely changes the dirt accumulation pattern on the screen, effectively using its straining area and increasing the time between cleanings. In addition, combining a convoluted strainer screen and unrestricted flow path results in a very low-pressure drop, ideal for applications such as condensate and boiler feed pump suction.

Strainer screens

Strainer screens are stainless steel or other specified materials

Cover type openings

For applications with infrequent basket changing, FLTR offers a simple, cost-effective, bolted cover type. In addition, it’s available with a davit assembly cover for larger strainers with heavy covers, making it possible for a one-person operation.

FLTR offers a hinged, quick opening cover secured by swing bolts for applications with more frequent changes. FLTR is adaptable for higher pressure applications. For medium-sized strainers, 14″ to 16,” a davit assembly bolted cover is available, allowing one operator to open the cover.

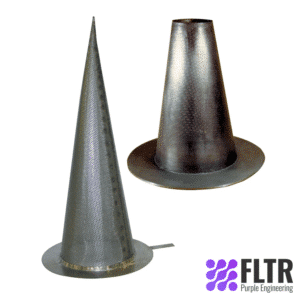

Model 92 Temporary Pipeline Strainer

Model 92 Temporary Pipelinestrainer is a device that is inserted temporarily in a pipeline to filter sediment and debris from fluids. It’s exclusive for piping start-up applications. It strains the fluid by guiding it through sized pores in the strainer.

Features

- ANSI classes 150, 300 and 600

- Perforations from 1/32″ to 1/2″ diameter

- Mesh liners of 20, 40, 60, 80 and 100

- (best with basket type strainers)

- Stainless steel or MONEL® construction

Options

Alloy construction, RTJ-style connections

Designed for use in

- New pipeline start-up service

- Line flushing after any modification work

-

Model 30R (NAFTA only)$1.00

Model 30R (NAFTA only)$1.00 -

Model 950B Duplex Offset Strainer Quick Opening Cover (QOC) 2-24 inch$1.00

Model 950B Duplex Offset Strainer Quick Opening Cover (QOC) 2-24 inch$1.00 -

Model 950B Duplex Offset Strainer Bolted Cover (BC) 2-24 inch$1.00

Model 950B Duplex Offset Strainer Bolted Cover (BC) 2-24 inch$1.00 -

Model 92 Temporary Pipeline Strainer$1.00

Model 92 Temporary Pipeline Strainer$1.00 -

Model 91 T Type 2-48 inch$1.00

Model 91 T Type 2-48 inch$1.00 -

Model 90 1-48 inch$1.00

Model 90 1-48 inch$1.00 -

Model 85 Y-Strainer$1.00

Model 85 Y-Strainer$1.00 -

Model 73 Straight Flow$1.00

Model 73 Straight Flow$1.00 -

Model 72SJ Steam Jacketed$1.00

Model 72SJ Steam Jacketed$1.00

Enter Keyword or Part Number

Then press enter for search results