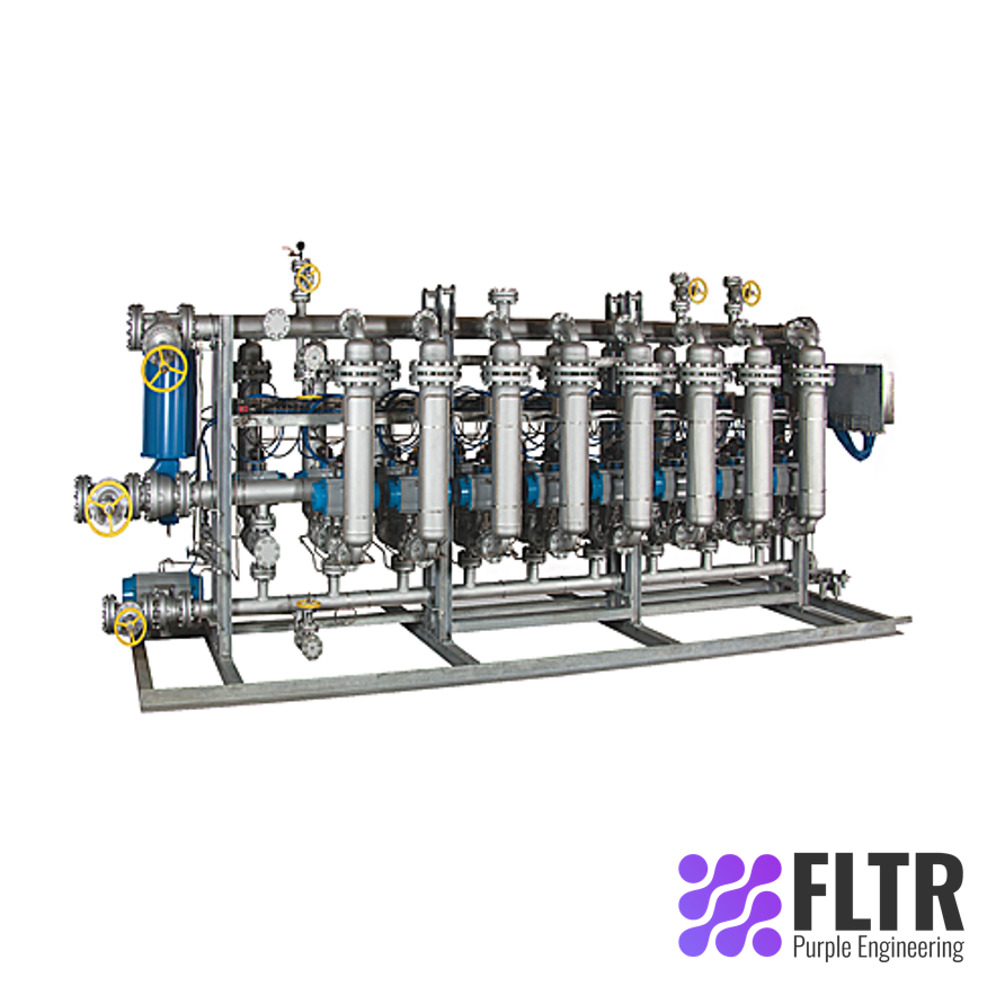

4000 Series ProGuard – Automated Back Wash Refinery Feed Filter System

Tubular backwashable filters are designed to remove solids from liquids by capturing solids on a permanent reusable wedgewire filter element. At a predetermined pressure differential, the system reverses flow through each filter element in the system, one element at a time, while the other elements continue filtering to provide continuous operation. 4000 series tubular backwash filter systems provide cost effective continuous protection for the life of catalytic reactors.

Request a Quote for

4000 Series ProGuard – Automated Back Wash Refinery Feed Filter System

Send us the details and we will get back to you.

The ProGuard automatic backflushing filter is specifically designed for the robust requirements of refinery streams for catalyst bed protection. It is important to remove particulate from the hydrotreater and hydrocracker feeds to protect the catalyst bed in the reactors and maintain the run life on catalyst beds at minimal cost.

For refineries to take advantage of opportunity crudes, the design of the filtration solutions needs to consider the higher variability in contaminants and the importance of optimized filtration systems cannot be overstated.

The ProGuard solution is designed to stand “Guard” and protect the catalyst beds. The solution can be tailored to the needs of the plant to suit the specific application.

Contact us to request a quote today.

| CARTRIDGE BASED SOLUTION | 4000 SERIES PROGUARD | FR SERIES PROGUARD | |

| Solution details | Low solids loading

Less than 450F Suitable for semi solids removal Versatile filtration capability |

Low moderate solids loading

Up to 750F Multiple backwash medium options (stream and liquid) for efficient contaminant removal |

Low to high solids loading

Up to 500F Versatile technology with wide application range |

| Typical applications | Hydrotreating and hydrocracking feed up to 450F except high temperature Gas Oil feed | Hydrotreating & hydrocracking for: • Resid • Gas oil • Heavy coker Gas oil product |

Hydrotreating and hydrocracking feed up to 500F. Coke Cutting Water, plant process and cooling water |

| Footprint | Small footprint | Large footprint | Medium footprint |

| Maintenance | Regular filter change outs based on dP | Periodic external cleaning of wedge wire filters. Half yearly valve maintenance |

Half yearly inspection and replacement of filter media on site |

| Operating cost | No recycle | Less than 2% recycle feed | Less than 0.1% recycle feed |

| Capital cost | Low | High | Moderate |

Less than 2% recycle feed

Hydrotreating & hydrocracking for:

- Resid

- Gas oil

- Heavy coker Gas oil product

Can't find what you're looking for?

Get in touch with us and we can help you find a solution.