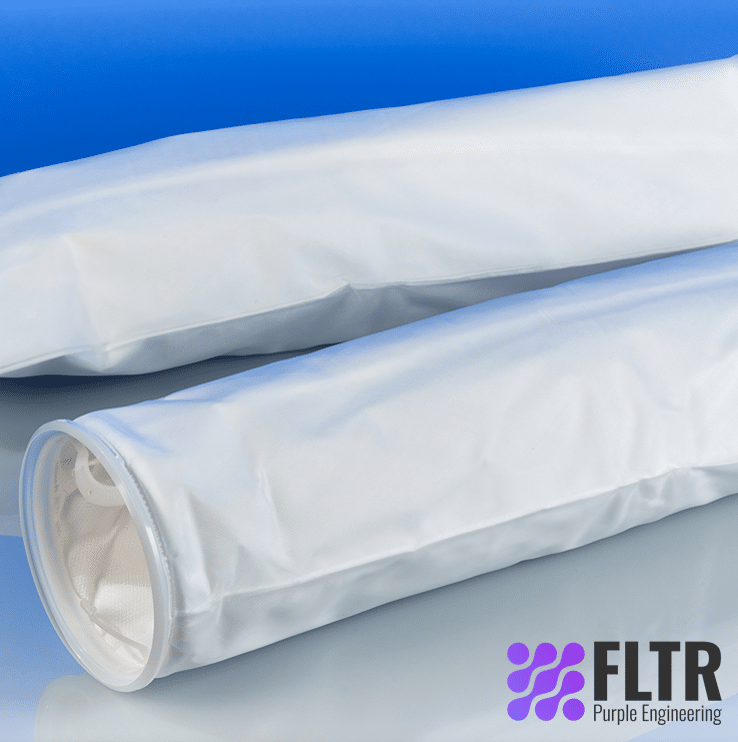

ACCUGAF filter bag

With efficiencies greater than 99%, each ACCUGAF filter bag model provides cost-effective filtration solutions for demanding applications. The five models ensure that users can efficiently remove particles ranging from 1 – 25 μm while delivering a long service life.

Request a Quote for

ACCUGAF filter bag

Send us the details and we will get back to you.

- ACCUGAF polypropylene filter bags are fabricated from hydrophobic microfiber filter material, which requires pre-wetting with an aqueous solution (full details about wetting and installation are provided with every box of ACCUGAF filter bags)

- Highly efficient melt-blown filter material in polypropylene or polyester with graded density profiles to maximize dirt-holding capacity and prolong the service life

- No additives such as resins, binders or surface treatments

- Double downstream cover layer virtually eliminates fiber migration

- Unique UNI-WELD process for bottom seam provides a stronger, more flexible weld seal

- Fully-welded construction with patented SENTINEL seal ring provides 100% bypass-free filtration

- The pressure-activated SENTINEL seal ring provides a flexible, chemically resistant seal that adapts to any bag filter housing

- Eaton strongly recommends the use of an insertion tool that facilitates the insertion of the filter bag into the bag filter housing and ensures the correct alignment of the filter bag inside the restrainer basket

Contact us to request a quote today.

| Materials | Melt-blown polypropylene or polyester | |

| Cover layers | Polypropylene or polyester mesh | |

| Seal rings | Welded polypropylene or polyester SENTINEL seal ring | |

| Retention ratings | 1.5, 3, 5, 10, 25 µm @ > 99% efficiency | |

| Sizes | 01: Ø 7 x 17” L (180 x 435 mm) 02: Ø 7 x 32” L (180 x 810 mm) |

|

| Filter area | 01: 2.6 ft² (0.24 m²) 02: 5.2 ft² (0.48 m²) |

|

| Max. operating temperatures | Polypropylene: 194 °F (90 °C) Polyester: 302 °F (150 °C) |

|

| Max. differential pressure | 36 psi (2.5 bar) | |

| Recommended change-out pressure for disposal | 11.6 – 21.7 psi (0.8 – 1.5 bar) | |

| Max. flow rates | 01: 35 GPM (8 m³/h) 02: 66 GPM (15 m³/h) |

Contact us for more information.

- Beer, wine, spirits and beverage filtration

- Fine particle removal in parts cleaning

- Final filtration of lacquers

- Final filtration of vinegar

- Activated carbon removal in process systems

- Hydraulic oils and lubricants

Can't find what you're looking for?

Get in touch with us and we can help you find a solution.