Here Is Why You Should Use FLTR Coolant Filter To Clean Your Sump!

Do you smell an awful smell at work? No matter where you looked, you were unable to discover its source. Most likely, the stench is created by your cutting fluid degrading. Are you thinking about what I can do? Don’t worry. Your sump needs cleaning. This article discusses sump cleaning and how the FLTR coolant filter is your best option.

Here’s the deal:

The connection between the FLTR coolant filter and sump cleaning

Sumps play a significant part in metal production and are the overlooked backbone of your machining operations. The fluid that cools cutting inserts and workpieces during the metal cutting process is stored in sumps. Sumps also gather debris and oil, thus allowing it to accumulate there. It can clog machinery and seriously harm its functionality.

The coolant starts to deteriorate whenever a sump is not operating, even for a brief time. Tiny microbes are chowing down on tramp oil that has gotten into your coolant due to leakage. The outcome includes a foul smell and the possibility of performance degradation for your cutting instrument. You may get rid of anything that might be hiding in your sump by doing routine sump cleaning and maintenance, including chips, swarf, mould, bacteria, and tramp oils.

If work operations need to stop for a short time throughout a weekend and you had not completed routine sump coolant maintenance, you might be in for some major and expensive issues.

How can you avoid those expensive repairs?

This is where FLTR coolant filter comes into play. This coolant fluid filter is a fine solution for all your sump cleaning. Why do you need to do sump cleaning? That’s an important thing you need to understand when you are going to use this coolant filter.

Let us dive into that first.

Why should you clean your sump? – Before discussing the FLTR coolant filter…

Do you know that regular sump cleaning and coolant refilling results in improved machine performance, fewer machine malfunctions, and less downtime for operators?

Your coolant fluid filter can impact the performance of your shop in several different ways.

You can keep the machine for a long time.

Your machines’ tooling can operate more effectively with routine coolant replacements and maintenance. Fresh coolant offers superior lubricity when cutting various materials, from soft metals to tough and fragile variations.

Efficient machine performance.

Tool holders, plates, and other machine parts may get sticky due to old or unclean coolant residue. Gummed-up components can slow down production, cause tools to misalign, and destroy drill bits and inserts

Machines sustain less wear and tear.

Due to inferior coolants, rust can develop on chucks, vises, ball screws, and other machine surfaces. This corrosion may result in early machine failure and expensive replacement with time.

How can you maintain a sump for many years?

Regular coolant review and laboratory testing, whether done internally or by the coolant producer, are crucial to any effective coolant maintenance program. This may be an expense you did not anticipate, especially if your organization has smaller coolant systems, depending on the size of your operation and the technologies you utilize.

Smaller coolant systems may be more costly to maintain and less capable of filtering than bigger systems, which may have the capacity to contain thousands of gallons of coolant. However, neglecting routine maintenance can soon result in subpar machine operation and system failure, costing you thousands in unanticipated outages, repairs, and laid-off workers.

Try these methods to change the sump coolant and increase the sump’s life.

- Drain all liquids from the sump completely.

- Ensure that your sump is clear of debris, chips, sludge, or muck.

- Fill the system’s filters and lines with water, then circulate them throughout.

- Fill in machine coolant sump cleaner in the recommended amount.

- If you cannot clean the sump in a while, circulate for a few hours or perhaps longer.

- Clear out all of the fluids from the system

- You can use fresh water to flush the system completely, and you should circulate water widely.

- Recommendations for coolant and water addition

- Make sure that the system is running at normal temperatures by circulating coolant across it.

FLTR coolant filter is the best option for you to clean the sump

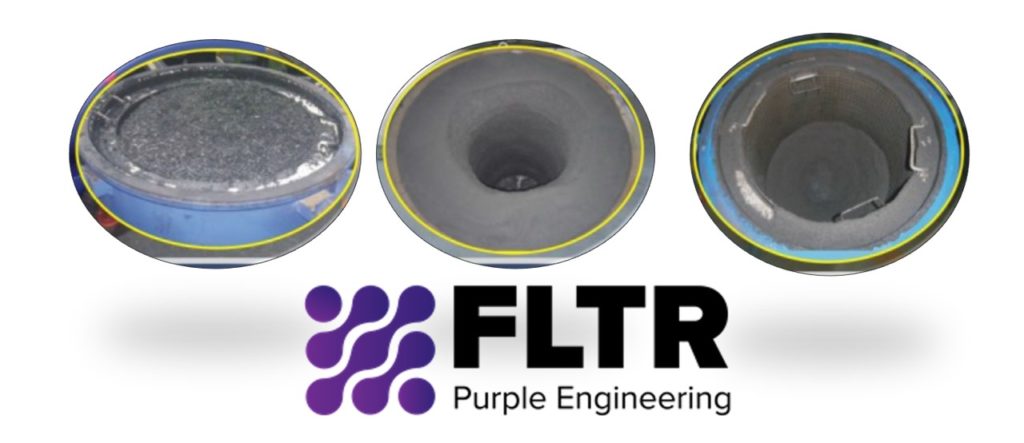

The FLTR-OM-Coolant Filter System, or Slump Cleaner, is the best option to clean sump in machines. You can save money by extending the life of your machine, tools, and coolants. The sump cleaner removes tiny debris from coolant and oil down to 10µ and below by inducing a vacuum in the tank. There are no consumables. Hence there are no ongoing expenses. The unit may be quickly cleaned of any accumulated filth and put back to work.

Characteristics of the cleaner

These are the features you get from the FLTR coolant filter.

- There is no Filter Element

- For your saving, reduced oil consumption

- For your benefit, an extended oil change period

- Cost-effective, reduced storage and disposal cost of waste oil

- For your benefit, reduced machine downtime

- For your work environment, reduced pollution and environmental Impact

How does it work?

FLTR Coolant Filter / Sump Cleaner cleans coolant and oil tanks by removing sludge, metal chips, and swarf and filtering it through a reusable steel mesh filter. The system functions based on the vacuum suction principle. A strong vacuum pump creates a vacuum in the unit’s tank, sucking up coolant, metal chips, swarf, and other debris and transferring it through a mesh basket. Clean coolant passes through to the unit’s tank while contamination is caught in the basket. The cleaned coolant is returned using a centrifugal delivery pump. You can use the machine in batch or continuous mode.

Where can you apply the cleaner?

There are many things you can apply to this slump cleaner. Such as Storage Tanks for CNC Machines, Soluble Cutting Oil, Neat Cutting Oil, and Water Emulsion.

What are the benefits of using a mobile sump cleaner?

- Slump cleaner removes coolant, chips, particles, and sludges quickly

- Reduces labour expenses and machine downtime

- Can regularly conduct sumps cleaning. Therefore, your sumps will have reduced swarf and chip buildup

- Vacuum/pressure gauges driven by air, electricity, or propane to avoid over-pressurization

- The CNC filter collects sludges, chips, and fines in a basket

Conclusion

One of the worst tasks in the shop is cleaning clogged machine reservoirs. But you can make it quick and pleasant work using an FLTR coolant filter. We discussed many uses and benefits you can get from the slump cleaner in this article. To make your sump cleaning easy, make the correct choice. Visit the below link to order your quote for FLTR-OM-Coolant Filter System (Slump Cleaner).

Enter Keyword or Part Number

Then press enter for search results